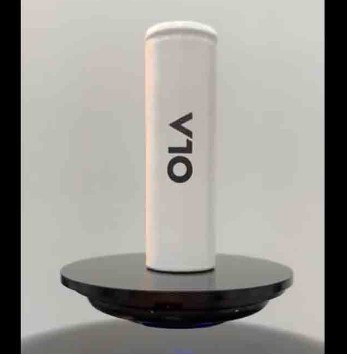

Ola Electric showcases indigenously made lithium ion cells

In a significant development that could herald self-reliance in production of electric vehicle batters in India, Ola Electric has succeeded in making a Li-ion cell indigenously. The success in making the Lithium Ion cell was announced by the Ola Electric CEO Bhavish Aggarwal on Twitter on Monday.

“The cell is the heart of the EV revolution. We need to make our own technology to scale faster and innovate. Much more in the pipeline on our cell technology roadmap,” Aggarwal said in his tweet. The clip showing the Li-Ion battery terming it as a milestone moment, has been viewed more than 70,000 times on twitter.

The current development can help India reduce its dependence on foreign countries, especially China for import of the EV batteries.

Ola and a few other companies including Mukesh Ambani’s Reliance Industries and Hyundai had recently won a tender under Department of Heavy Industry’s $2.4-billion ‘National Programme on Advanced Chemistry Cell (ACC) Battery Storage’. Under this programme, the Government will give incentives over five years and it aims to achieve a manufacturing capacity of 50 GWh of ACC.

The firms are expected to set up manufacturing facilities in India, conduct research and development and facilitate demand creation for battery storage in the country. All the demand of the ACCs in India now is currently being met through imports, mainly China.

Batteries account for a major cost of an EV, depending on range and performance. Continued increase in global battery prices in the last few months threaten to impact demand for EVs in the domestic market.

Demand

There are currently 12 lakh electric vehicles in the country. By this year end, the number is expected to touch 40 lakh and reach three crore in two years. By 2035, India will need about 3,400-4,100 gigawatt hours (GWh) of lithium-ion batteries. India remains heavily reliant on the international market for EV components, especially battery cells. Mostly, it is imported from China, which started its battery technology research in 2001.

Types of batteries used in EVs

Lithium-ion

This is a widely used battery in the electric car industry. Its smaller versions are already used in mobile phones and laptops. Lithium-ion batteries have better power-to-weight ratio, the mileage per charge is high. It has a low self-discharge level, making it easy to maintain. Also, most components of the Li-ion batteries can be recycled.

Hybrid Nickel-Metal (NIMH)

Hybrid cars that have both battery-powered and fuel-powered engines mainly use Nickel Metal Hydride (NIMH) batteries. These also find a use in EV cars. These batteries do not require any external power source to charge. Their charging depends on regenerative braking, speed, and wheels of the car. NIMH batteries have a better lifecycle and are safer too, but have a high self-discharge rate. These also generate heat in high temperatures.

Lead-Acid

Lead acid batteries are heavier and lose power over time. Automobile companies have been using them for long due to lower pricing. They are not yet used on consumer electric vehicles. This battery is used as a secondary storage system for commercial vehicles. They are recyclable.

Solid state

A Solid State battery uses a solid electrolyte instead of a liquid as seen in Lithium-ion batteries. The energy density is high. These are aimed to last longer, be safer and compact. However, these batteries are still in early stages of development.

With the focus on encouraging electric vehicles, there is heavy dependency on batteries and going by the statement of union Minister Nitin Gadkari, the prices of EVs will be equal to the cost of petrol vehicles within one year.

ends